METAL CEILINGS: MATERIALS AND FINISHES

Our metal ceilings are made of galvanized steel or top-quality aluminum.

Various finishes are available, depending on the material, format, product and quantity.

- 25 micron polyester coating (prepainted), available in several colors, such as mat white (about 15% gloss), or metallic gray on steel, and other colors on aluminum products (linear strips, open-cells).

- 80 micron polyester powder coating (postpainted), available in 180 mat shades (about 30% gloss). These colors are taken from the color chart. Gloss colors (about 80% gloss) are also available.

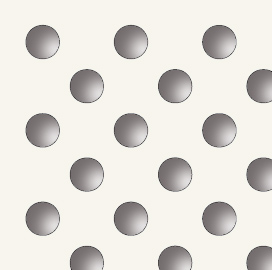

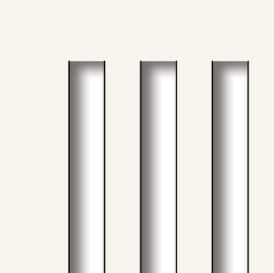

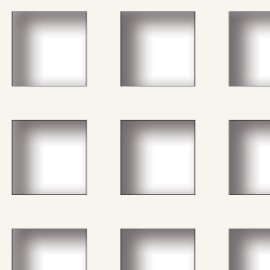

PERFORATIONS

The perforations in metal ceilings address the need for acoustic comfort. They also contribute to the decorative aspect of the ceiling.

Plafometal proposes a broad selection of perforations (see below). Other decors can be considered on request.

THE FOUR CRITERIA THAT CHARACTERIZE PERFORATIONS

When perforating a ceiling to transform it into an acoustic metal ceiling, four vitally important criteria must be met.

- Perforation rate or air space ratio

- The shape and size of the holes

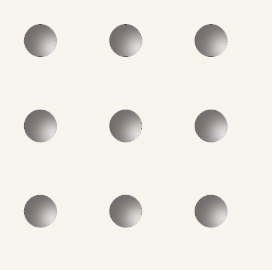

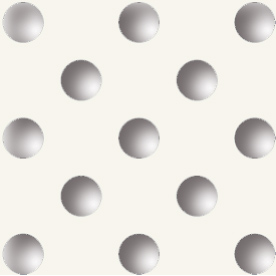

- The arrangement of the holes (in an “M” for regular staggered rows at 45°, and in a “U” for regular perforation in lines)

- The range of the perforation There are three types of perforations for metal ceilings:

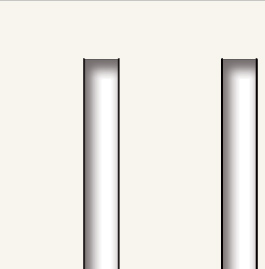

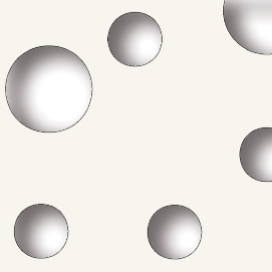

- Central perforation: this type of perforation stops short of the four sides of the visible panel, leaving a smooth peripheral border.

- Continuous perforation stops short of the two longitudinal sides and continues to the edge of the visible panel.

- In full perforation, the entire surface is perforated, including in the folds of the visible panel.

To go further